Advanced bioethanol

Bioethanol is a biofuel obtained through an industrial fermentation process that transforms biomass sugars into alcohol.

What is bioethanol?

Bioethanol is a biofuel obtained through an industrial fermentation process that transforms sugars from biomass into alcohol. It is mainly used as an additive in engines that use gasoline or also as a pure fuel in adapted engines (flex fuel).

Common blends are E5, E10 and E85, with ethanol contents of 5%, 10% and 85%, respectively.

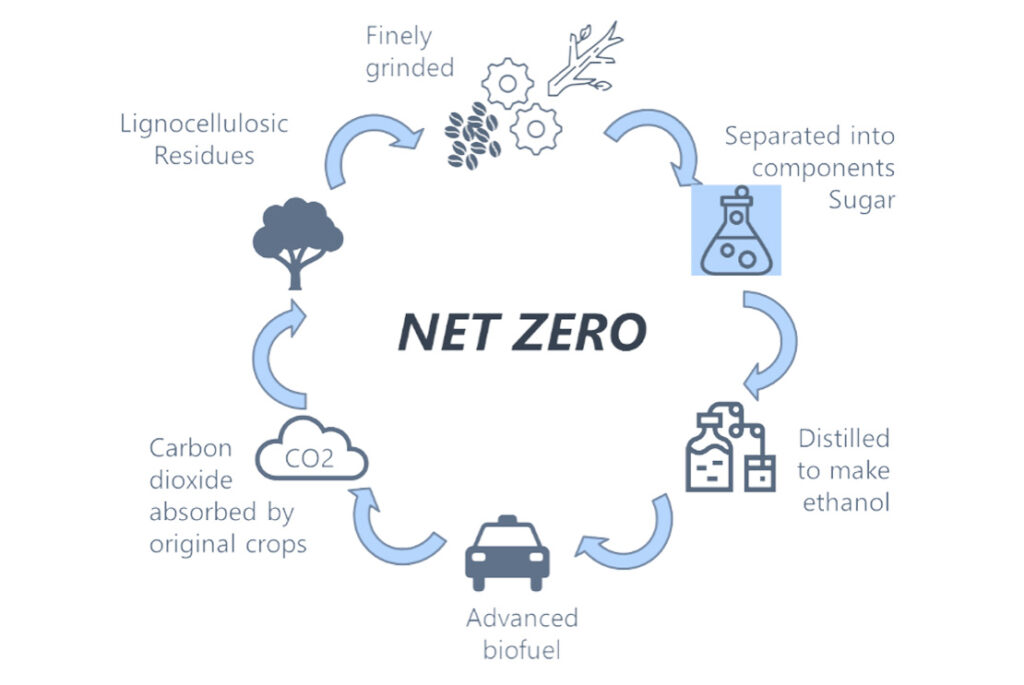

It is considered a net zero source of energy since the CO2 expelled by the car’s combustion is absorbed by plants while growing, which are later transformed into ethanol.

- First generation bioethanol comes from the alcoholic fermentation of sugars and starches found, for example, in sugar cane, wheat or beets.

- Second generation, also known as Advance Bioethanol, is obtained through the degradation of the lignocellulosic materials of agricultural and forestry residues such as tree pruning or wheat straw.

Which is the regulatory framework in the EU?

The EU is working on the transition towards advanced biofuels made from sustainable feedstock. According to the Renewable Energy Directive 2018/2001/EU (RED II), by 2030, the EU aims to increase the share of renewable energy in transport to at least 14% including a minimum share of 3.5% of advanced biofuels. In EU legislation, advanced biofuels are defined by the feedstock used. In its relevant section (Part A of Annex IX) RED II clearly establishes the types of biomass that are accepted for advanced biofuels production.

RED II is already driving demand on advanced biofuels and, on top of that, Fit for 55 legislative proposals package will likely rise demand above the mandate levels of RED II.

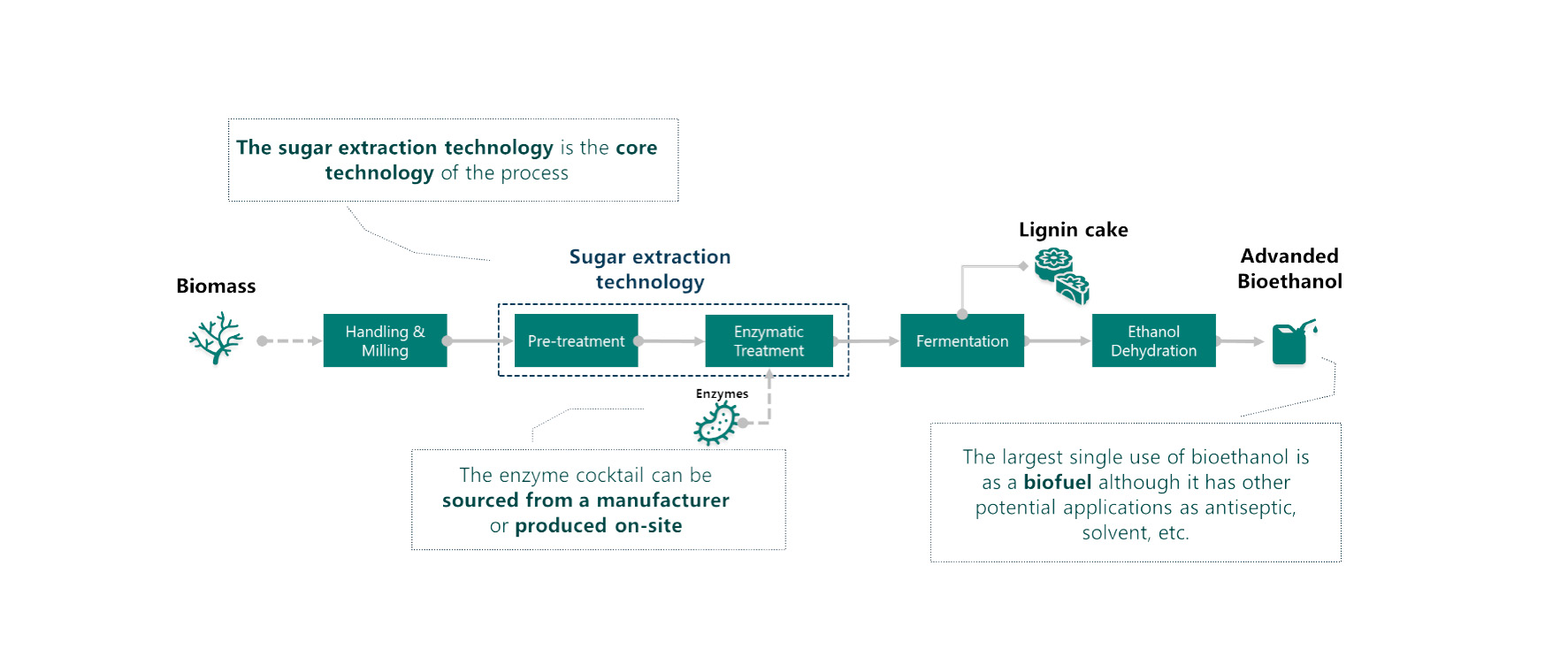

How is Advanced Bioethanol produced?

Advanced Bioethanol production is based on the enzymatic breakdown of biomass into simple sugars. Commonly, these plants comprise the following units:

- A biomass treatment unit that removes impurities. Additionally, the particle size will be reduced at a milling stage to suit the requirements of the process.

- A bioethanol production plant, which operates with licensed technologies from a top-tier technology provider. The process consists of a first stage of pretreatment in which part of the sugars present in the biomass are released. Next, the pretreated biomass will undergo an enzymatic hydrolysis process that will release the remaining sugars. Once the biomass is separated into its constituent fractions, the sugars are fermented while the lasting fraction, formed mostly by lignin, will be used as fuel for the generation of the energy.

- A cogeneration plant adapted to use the lignin obtained from biomass processing as fuel to provide heat and power.

- An anaerobic treatment plant, which renders an effluent suitable to be discharged into a conventional sanitation network and biogas which could be upgraded in the facility to biomethane.

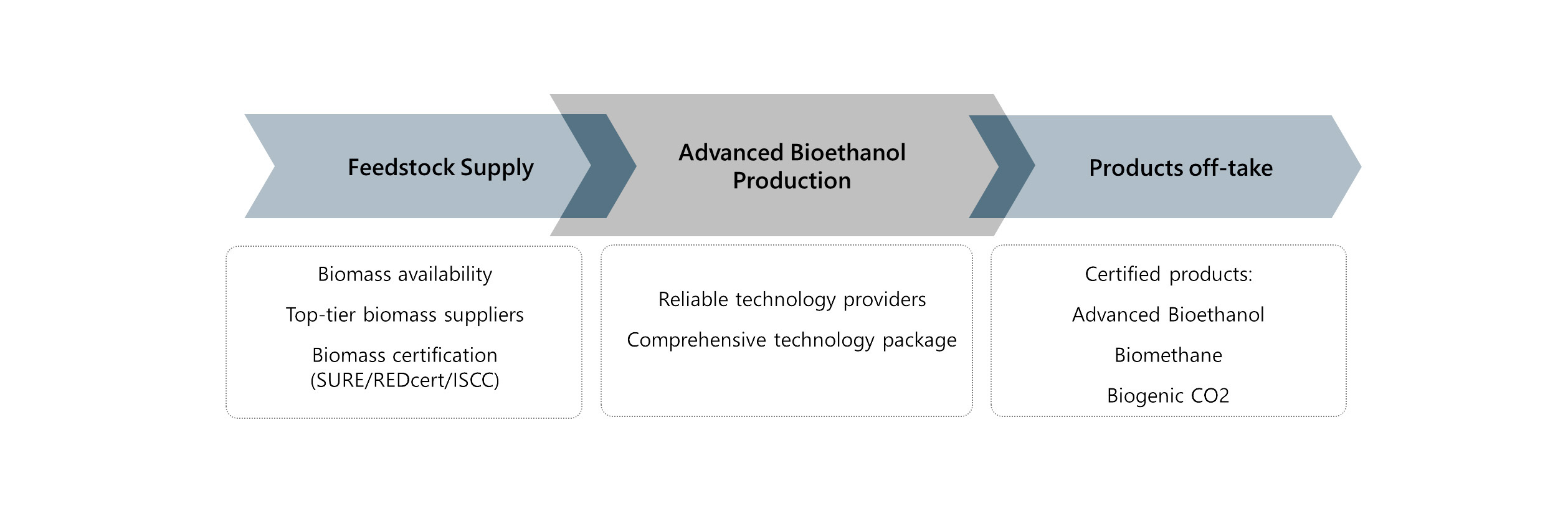

What is our value proposition?

Besides our experience in the construction of large industrial plants and process integration, in track we help our clients develop and structure Advanced Bioethanol projects by providing expert advice on the entire value-chain, including, among other, the feedstock supply and product off-take, or the technology screening and selection.