The Hydrogen opportunity

Hydrogen is a critical piece in the challenging puzzle that is the global energy transition.

What is hydrogen? And what different types currently exist?

Hydrogen is a critical piece in the challenging puzzle that is the global energy transition. Although today it is mostly used in the refining and chemicals sectors, its potential as a clean energy vector across multiple sectors make it one of the fuels and feedstocks that will enable the decarbonization of some of the hardest industries to abate.

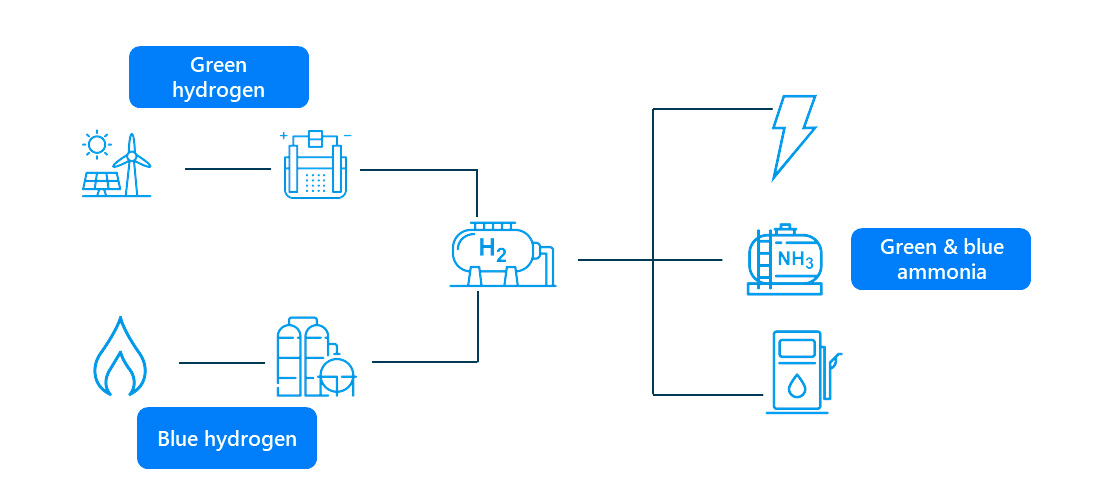

The same hydrogen can be produced using different processes, leading to a color-based classification according to the production process. The different hydrogen types are:

- Grey hydrogen: produced via steam methane reforming (SMR), which involves combining natural gas with high-temperature steam to produce hydrogen and carbon dioxide. This production process is the main pathway used today in the industry. Grey hydrogen could eventually phase out as new, cleaner types of hydrogen become increasingly available.

- Blue hydrogen: produced in the same process as grey hydrogen, with the difference that it includes a carbon dioxide capture unit. The CO2 is captured and used or stored, rendering the hydrogen essentially zero emissions. This type of hydrogen is expected to grow in relevance, as natural gas producers advance in their decarbonization journeys.

- Green hydrogen: produced via water electrolysis, a process in which electrical current is used to split water into hydrogen and oxygen, powered by renewable energy sources such as solar and wind. This type is considered a very clean form of energy, as there are no greenhouse gas emissions nor other pollutants when produced. It has the potential to provide a clean, renewable, and abundant source of energy, particularly in geographies with good renewable resources.

- Pink hydrogen: also produced via water electrolysis, in this case powered using nuclear energy. Yellow hydrogen is considered a clean source of energy, given the absence of greenhouse gases in the whole process, although there is waste associated to the nuclear power generation.

Other colors exist, depending on the process used or the source (e.g., coal, biomass).

What is hydrogen used for?

Additionally, it is one of the key components in synthetic fuels, such as ammonia, e-methanol, etc., which can then be used as fuel for means of transport that currently rely on fossil fuels. The uses are multiple and are bound to grow in importance over the next decades, given that using green or blue hydrogen for these applications will be a driver of the decarbonization of the global economy.

According to the IEA (International Energy Agency), the demand for hydrogen recovered in 2021 to above pre-pandemic levels by reaching 94 million tonnes (about 2.5% of global final energy consumption). Traditional uses in refining and industry accounted for most of it, although demand for new applications grew approximately 60% from 2020. This is an indication that demand for hydrogen is increasing as more countries and industries are looking to reduce their reliance on fossil fuels and move towards clean energy sources.

What are the key technologies for green hydrogen?

Some of the key technologies to boost the growth of green hydrogen supply include:

- Electrolyzers: are the key device that enables the use of electricity to split water molecules into hydrogen and oxygen. There are two main electrolyzer technologies: alkaline and polymer electrolyte membrane (PEM). As many of these technologies are being developed, track’s technical team has close relations with the leading electrolyzer manufacturers (OEMs) and stays updated in the development of technological advances.

- Renewable energy sources: to produce green hydrogen, renewable energy sources such as solar, wind, hydro, or geothermal energy are used to power the electrolysis. Green hydrogen operation costs are mainly driven by power costs; therefore, competitive renewable power is critical to ensure the economics of a green hydrogen project.

-

- Energy storage: energy storage, such as batteries, can become a key element to account for the intermittency of supply in many of the renewable energy sources (e.g., solar and wind), and to ensure a steady supply of electricity to the electrolyzers. This, in turn, would enable higher efficiencies in the electrolytic process, and have a positive impact in the economics of green hydrogen projects.

- Transportation: the transportation of hydrogen gas is a relevant consideration in the green hydrogen supply chain, given some of the associated technical challenges. Increasing blending of hydrogen into existing gas pipelines, developing dedicated hydrogen pipelines, and building the infrastructure to convert clean hydrogen into ammonia for overseas transport, will be critical to achieve the full potential of hydrogen as a fundamental enabler of the energy transition.

What can track do?

Our mission is to support our clients across the whole green / blue hydrogen production value chain, from the initial development of the project (from an early concept) to the production of hydrogen and derivatives (e.g., ammonia), including the engineering and the EPC of the plant.

We have experience in building large complex plants and a deep knowledge of the full value chain.